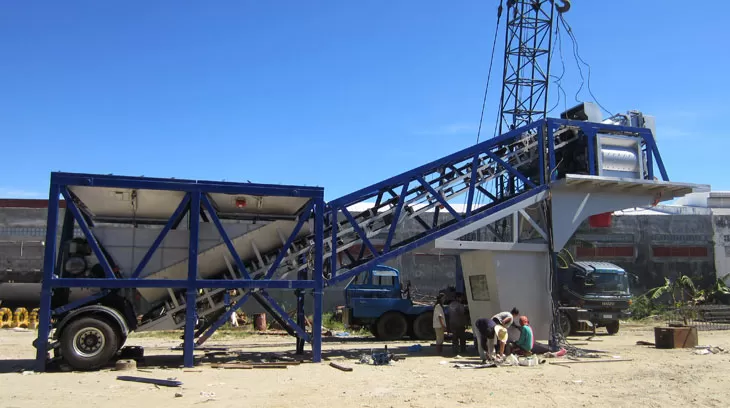

Twin Shaft Mobile Concrete Batching Plant

Capacity : 20-120m³/h

Power : 30-150KW

Discharge height : 1.5~4.2(m)

Price : 26000 - 150000USD

Get a quoteWhatsAppTwin Shaft Mobile concrete batching plant and stationary concrete batching plant have identical processes, operation methods, and maintenance procedures. They share the same actions and operate in the same manner. However, mobile concrete batching plant have unique features such as mobility, quick and easy assembly and disassembly, and simple storage management.

What is the working process of the Mobile concrete batching plant?

- 1.Aggregate Batching: The aggregates (such as sand, gravel, and crushed stone) are accurately measured and batched using a batching machine or system.

- 2.Cement and Additive Weighing: The cement and additives (if required) are weighed and added to the mixing process based on the predetermined mix design.

- 3.Mixing: The aggregates, cement, additives, and water are mixed together in the concrete mixer (which can be a twin-shaft mixer, planetary mixer, or drum mixer) to produce the desired concrete mixture.

- 4.Discharging: Once the mixing is complete, the concrete is discharged from the mixer into a transit mixer truck or a concrete pump for transportation to the construction site.

The operation methods for controlling the batching process, adjusting mixing parameters, and monitoring the equipment are similar for both mobile and stationary plants. They typically involve the use of a control panel or computerized control system, allowing operators to set the desired mix proportions, monitor the mixing process, and make adjustments as needed.

In terms of maintenance and upkeep, mobile and stationary concrete batching plant require regular inspection, cleaning, lubrication, and replacement of worn-out parts. Maintenance schedules may vary based on the specific equipment and manufacturer's recommendations.

Overall, while the processes and operational aspects of mobile and stationary concrete batching plant are the same, the unique advantages of mobility, quick assembly/disassembly, and simplified storage management make mobile plants a preferred choice for projects that require flexibility and frequent relocation.

Technical Specifications

| Model | YHZS25 | YHZS35 | YHZS50 | YHZS75 | YHZS100 | |

|---|---|---|---|---|---|---|

| Capacity (m3/h) | 25 | 35 | 50 | 75 | 100 | |

| Concrete mixer | Model | JS500 | JS750 | JS1000 | JS1500 | JS2000 |

| Mixing power (kw) | 18.5 | 30 | 18.5×2 | 30×2 | 37×2 | |

| Output per batch (m3) | 0.5 | 0.75 | 1 | 1.5 | 2 | |

| Max. aggregate size | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | |

| Aggregate bin (m3) | 2×8 | 2×8 | 4×8 | 4×8 | 4×10 | |

| Walking speed (km/h) | 20 | 20 | 20 | 20 | 20 | |

| Weighing accuracy | Aggregate | 1200±2% | 1800±2% | 2400±2% | 3600±2% | 4800±2% |

| Cement | 300±1% | 450±1% | 600±1% | 800±1% | 1000±1% | |

| Fly ash | / | / | 150±1% | 200±1% | 300±1% | |

| Water | 150±1% | 200±1% | 400±1% | 400±1% | 500±1% | |

| Additive | 20±1% | 20±1% | 30±1% | 30±1% | 40±1% | |

| Discharge height (m) | 3.8 | 3.8 | 4 | 4 | 4 | |

| Total power (kw) | 40 | 55 | 75 | 105 | 135 | |