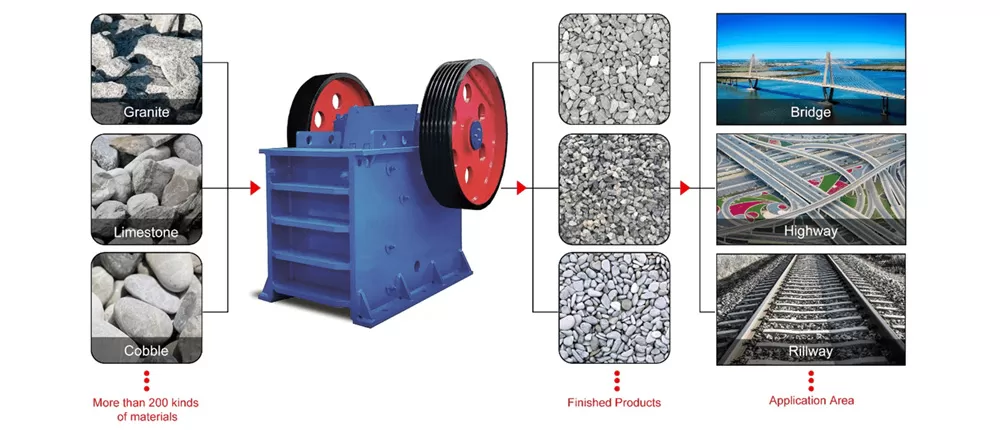

Jaw Crushers

Capacity : 1-600(t/h)

Feed size : ≦300-1020(mm)

Discharge size : 20-350(mm)

Motor Power : 30-220(KW)

Price : - USD

Get a quoteWhatsAppThe PE series jaw crusher is an early crushing equipment known for its simple structure, robustness, reliable operation, easy maintenance and repair, as well as lower production and construction costs. It is commonly used as a primary crusher in various stone production lines and ore crushing production lines. It is widely used in industries such as mining, metallurgy, building materials, highways, railways, water conservancy, and chemicals. It can process various ores with a compressive strength of up to 320MPa into medium-sized particles in one step. The product achieves the crushing purpose by squeezing, rubbing, and grinding materials in the crushing chamber through the reciprocating motion of the movable jaw and fixed jaw plates. In recent years, to meet the needs of crushing high-strength and high-hardness ores in metallurgy, mining, construction, etc., a powerful jaw crusher has been specially developed.

Core Advantages:

High crushing ratio and uniform particle size, high production efficiency

① Optimized deep cavity crushing with a large inclination of the elbow plate, large stroke, and reasonable rotational speed, allowing for larger feed size, higher output, and more uniform particle size.

② Digital analysis of the operation of each component, heavy eccentric shaft forged processing, high manganese steel jaw plates, and high-grade cast steel movable jaw assembly, resulting in a crushing ratio of approximately 15, significantly improving production efficiency, and increasing processing capacity by 20-35% compared to conventional jaw crushers of the same specification.

Simple and stable body structure, easy operation, and maintenance

① Adopts the traditional compound pendulum basic design principle, with a simplified structure, making it easier to operate and maintain.

② Equipped with a special centralized lubrication system for convenient component replacement, faster lubrication, and reduced maintenance workload.

Longer service life, reduced production costs, optimized selection of core components, and precision machining

① The core components are made of highly recognized and excellent high manganese steel castings, resulting in a longer service life, reduced maintenance and downtime, and lower production costs.

② The design of the double-curved concave plate reduces wear, and under the same process conditions, the life of the concave plate can be extended by 3-4 times or more.

③ Perfect machining, heat treatment, and non-destructive testing ensure that the eccentric shaft has sufficient strength and stiffness, thereby extending its service life.

Technical Specifications

Model | Feed opening (MM) | Max.feed size(MM) | Outlet adjustment (MM) | Capacity(T/H) | Speed (R/MIN) | Power (KW) | Dimension (LxWxH) (mm) |

PE-150x250 | 150x250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 720x660x850 |

PE-200x300 | 200x300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 910x750x990 |

PE-200x350 | 200x350 | 180 | 18-70 | 3-10 | 260 | 11 | 1000x870x990 |

PE-250x400 | 250x400 | 210 | 20-60 | 5-20 | 300 | 15 | 1300x1090x1270 |

PE-400x600 | 400x600 | 340 | 40-100 | 16-60 | 275 | 30 | 1730x1730x1630 |

PE-500x750 | 500x750 | 425 | 50-100 | 40-110 | 275 | 55 | 1980x2080x1870 |

PE-600x900 | 600x900 | 500 | 65-160 | 50-180 | 250 | 75 | 2190x2206x2300 |

PE-750x1060 | 750x1060 | 630 | 80-140 | 110-320 | 250 | 110 | 2660x2430x2800 |

PE-900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 200 | 132 | 3380x2870x3330 |

PE-1000x1200 | 1000x1200 | 850 | 195-300 | 280-560 | 200 | 160 | 3480x2876x3330 |

PE-1200x1500 | 1200x1500 | 1020 | 150-350 | 400-800 | 180 | 220 | 4200x3300x3500 |

PE-1500x1800 | 1500x1800 | 1200 | 220-350 | 500-1000 | 180 | 280 | 5160x3660x4248 |

PE-1600x2100 | 1600x2100 | 1500 | 300-400 | 1300-2200 | 160 | 380 | 6210x4013x4716 |

PEX-150x750 | 150x750 | 120 | 18-48 | 8-25 | 320 | 15 | 1200x1530x1060 |

PEX-250x750 | 250x750 | 210 | 25-60 | 13-35 | 330 | 30 | 1380x1750x1540 |

PEX-250x1000 | 250x1000 | 210 | 25-60 | 16-52 | 330 | 30 | 1560x1950x1390 |

PEX-250x1200 | 250x1200 | 210 | 25-60 | 20-61 | 330 | 37 | 2140x1660x1500 |

PEX-300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 300 | 55-75 | 2720x1950x1600 |